DMT Diamond Sharpener (FINE) Professional

DMT Diamond Sharpener (FINE) Professional is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

United States: Free standard shipping on orders over $200.

Canada: Free standard shipping on orders over $100 to BC, AB, SK, MB, and ON

Delivery Times

Canada: 3-7 business days after processing.

**Please note**

Canada Post is currently on Strike which may delay shipping times

- We have other shipping providers available.

United States: 5-10 business days after processing.

For More information, please see our Shipping Policy

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

The DMT Difference

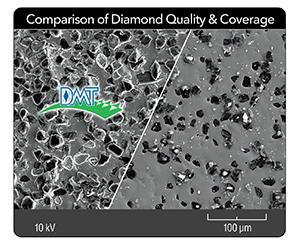

Diamond Uniformity, Coverage, Surface FlatnessUniformity: DMT uses micronized monocrystalline diamonds, precisely sized for a more uniform diamond surface. No other diamond sharpeners offers micronized monocrystalline diamond and most offer the lesser grade poly-crystalline diamond. Mono-crystalline is like an ice cube made up of one particle holding its form while poly-crystalline is like a snow-cone made up of many small particles that get sheared off during use.

Coverage: DMT’s process assures the most diamonds per square inch in the industry providing a more durable sharpening surface.

Surface Flatness: DMT bench stones are engineered flat, assuring even contact with the knife or tool.

Choice of Diamond Surfaces

Interrupted or polka dot surface for which DMT is famous has slightly recessed holes that will collect metal fines (swarf) removed during sharpening to prevent loading. Fast sharpening action; not recommended for pointed or very small tools.

Continuous surface presents a more conventional looking sharpening surface. Fast sharpening action; able to use on small surface edges.

HardCoat, DMT’s newest proprietary surface, is able to withstand the rigors of ceramic sharpening, providing an even longer service life to the sharpener.

DMT Commitment

DMT is committed to providing the best